At one point in Trenton’s history, the city was known as the Staffordshire of America due to the large number of pottery factories operated in across Trenton. For Historic Trenton’s Day in the Life, we’re looking back through newspapers from the beginning and examining everyday problems, solutions, and needs during historic Trenton’s past. Today, we look at the rise, peak, and fall of the booming pottery industry in Trenton.

The industry started to grow in the 1850’s; the only pottery in Trenton was small redware pottery operated by the McCully family. In 1853, two more operations opened. Taylor and Spieler began production of a line of Rockingham in May 1853. It was followed shortly after that by William Young & Co. William Young, his sons, Richard Millington and John Astbury, were associated with this endeavor for about six years.

By the 1860s and 70s, the industry grew to a dozen different industrial potteries across the city. The Etruria Pottery and the Excelsior Pottery were located along the Delaware and Raritan Canal, most notably, in the section of the town known as Coalport. Here, railroads emerged and were used to unload coal for industrial use.

Trenton was optimal for the growth of the pottery industry due to its placement near the Delaware River, the Delaware and Raritan canal, and the dozens of different railroad lines that came into the city. This would allow the City of Trenton to contribute to the American pottery industry’s growth. According to Ellarslie.org, Trenton pioneered the development of art porcelain through the introduction in 1882 of “Belleek” china. Using techniques developed at the Irish Belleek works, Trenton became the base for high-quality art porcelains.

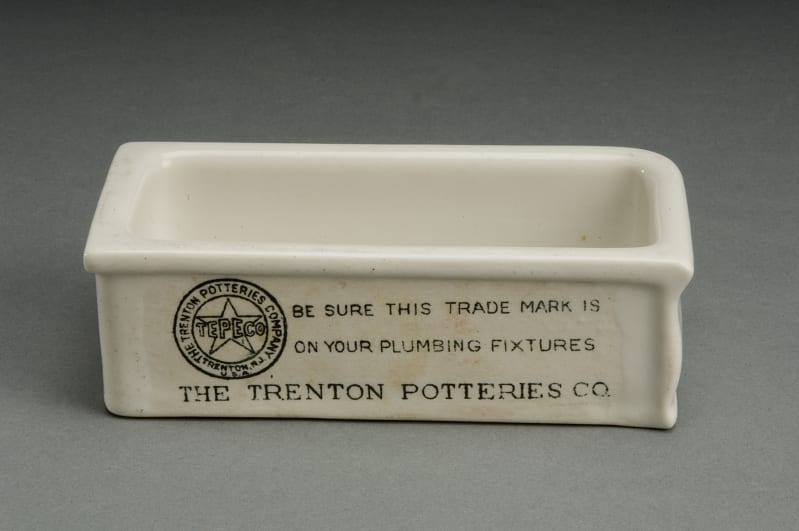

Trenton also led the nation in crucible making, fire-brick and terracotta manufacturing, kiln furniture production, the grinding of flint and spar (for use as clay tempering materials), and pottery decorating. According to Potteries of Trenton NJ Society, at the industry’s peak, roughly 1880 and 1920, only one other industrial center in the United States (East Liverpool, Ohio) came close to challenging Trenton as the nation’s leader in pottery manufacture.

Between 1850 to 1940, over 100 entries for industrial pottery manufacturing sites in Trenton. Ellarslie.org explained that there has never been a comprehensive history of Trenton potteries, primarily because of the massive scale of the industry.

The sector hit its peak in the early 1900. Across the nation, Americans were using Trenton pottery. In 1902, created by the J.L Mott Company of Trenton, the first presidential bathtub was installed in the White House for President Taft. The bathtub accommodated the president’s size, which meant it could hold four grown men comfortably.

By the depression, the number of pottery plants went from over 100 to about 30 across the city. By World War 2, it dropped to 18. This was due to many factors, including redirecting energy resources from consumer goods to the war efforts. According to the Potteries of Trenton NJ Society, other factors that contributed to the decline included labor disputes, resistance to the introduction of new labor-saving technologies, and the increasing use of plastics in the home.